Capabilities

Equipped with advanced technologies and automated systems, we operate in GMP-compliant cleanrooms built with energy-efficient and sustainable design principles. Every process is engineered to meet or exceed the most rigorous global safety and quality standards, ensuring consistency, sterility, and excellence at every stage of production.

Manufacturing Facilities

Our state-of-the-art manufacturing facilities are designed to support the safe and scalable production of both vaccines and injectable biologics.

Vaccines

Drug product facilities capable of formulation from 20L to 800L, filling in vials

Our R&D team is currently focused on developing vaccines and biologics for high-priority public health needs, We also collaborate with academic institutions to support advanced training and encourage Ph.D. research among our employees.

Warehouse and distribution centres to handle raw materials, packing materials, consumables, semifinished, finished goods and seed lots &cell banks

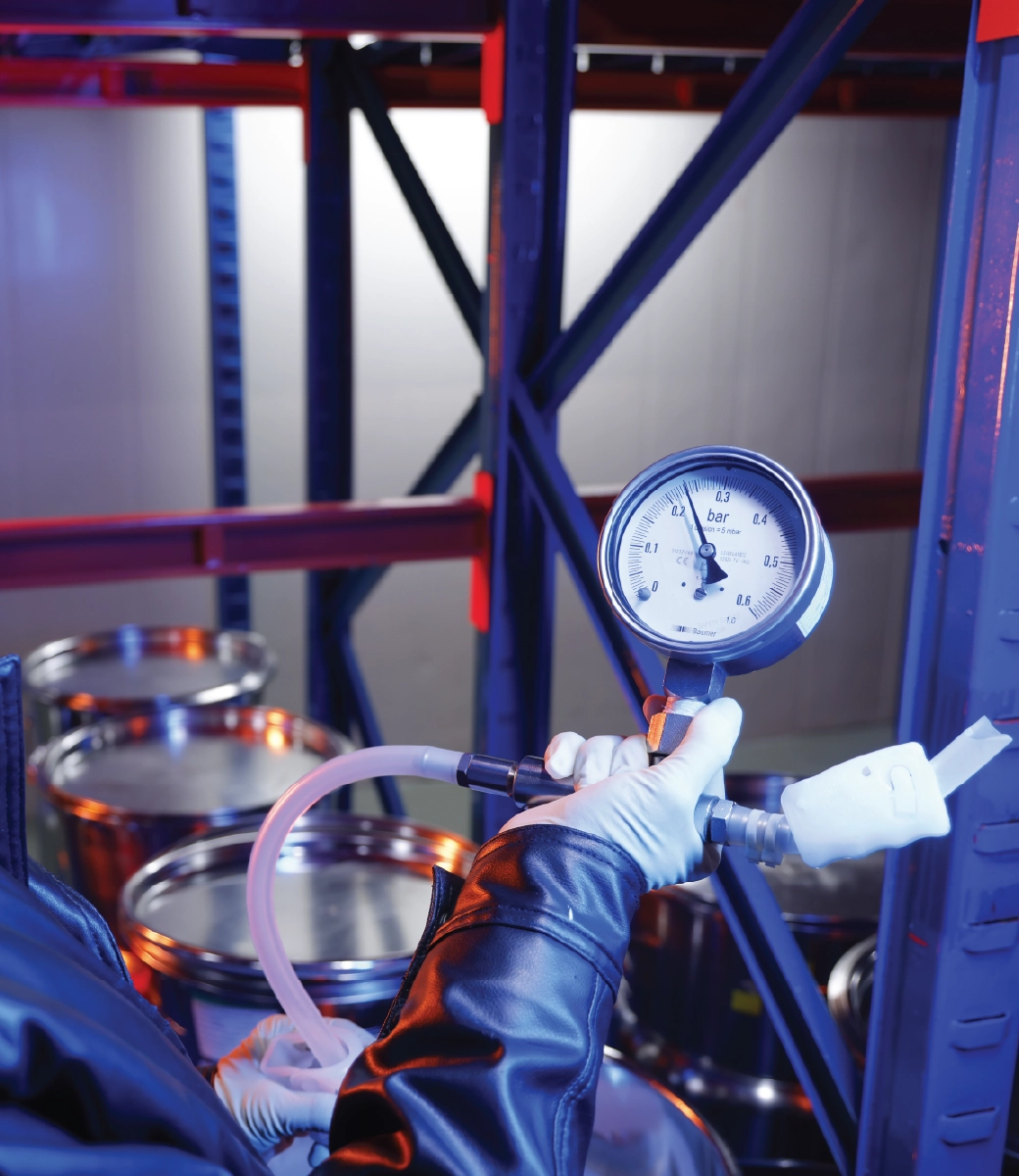

Injectables

Sterile Injectable Contract Manufacturing Focused on Insulin & Cartridge-Based Delivery Systems

GMP-Compliant CMO with specialization in insulin and other cartridge-based injectable products

High speed Isolator-based aseptic fill-finish lines with full automation: washing, siliconization, depyrogenation, filling, stoppering, sealing,

Advanced component processors. 100% automated visual inspection lines

Isolator for sterility testing

Tech Transfer Expertise: Formulation adaptation, analytical method transfer, with Dedicated cross-functional project teams that ensure on-time tech transfer and batch execution

Collaborative approach with end-to-end lifecycle support for injectable products

Cold-chain enabled logistics and serialization-ready packaging lines for global compliance

Facility and systems aligned with EU Annex 1, US FDA, WHO GMP, and Schedule M

Fully validated utilities and controlled environments for cleanroom operations

Automation & Pharma 4.0 Integration

Digitally enabled operations with PCS 7, SCADA, EMS, BMS, LIMS, and ERP systems integrated across the facility

Real-time data acquisition, audit trail management, and 21 CFR Part 11 / Annex 11 compliance

Advanced process control systems for ensuring reproducibility, traceability, and continuous improvement

Digital QMS ensuring streamlined deviation, CAPA, change control, and batch release workflows

The QC lab at our injectable facility ensures product quality, safety, and compliance through validated analytical and microbiological testing on raw material, in-process, and finished product testing.

All analytical methods are GMP-compliant and ICH-validated, and aligned with global regulatory standards. With meticulous documentation, regular audits, and continuous training/improvement, the dedicated QC lab plays a vital role in delivering high-quality product, ensuring each dose is safe and effective for public use.

Quality Control Laboratories

Quality Control (QC) laboratories at vaccine plant ensure the safety, efficacy, and quality of the vaccines through stringent control of materials, production processes, and final products.

Our state-of-the-art 50,000 sq.ft. R&D center supports the full spectrum of vaccine development—from pre-clinical studies to product licensure. The facility houses specialized laboratories for molecular biology, immunology, fermentation, purification, cell culture, hybridoma technology, and virus handling, making it ideally equipped for advanced vaccine and biologics research. The R&D center is further supported by a scientific library, lecture hall, centralized monitoring systems, and all essential utilities—creating a fully integrated and modern research environment.

Our R&D team is currently focused on developing vaccines and biologics for high-priority public health needs, We also collaborate with academic institutions to support advanced training and encourage Ph.D. research among our employees.

At GCBC, we believe strongly that collaboration with national and international organizations is key to advancing vaccine innovation and accelerating the path from research to commercialization. These strategic partnerships play a vital role in ensuring that safe, effective, and affordable vaccines reach those who need them most across the globe.

Research & Development

GCBC Vaccines is a research-driven organization that invests into R&D to address critical global health challenges. Backed by strong scientific partnerships and a highly skilled team, our R&D efforts uphold the highest standards of scientific integrity, end-to-end development excellence, and robust pharmacovigilance.

Clinical Development and Medical Affairs

Clinical research is central to vaccine development at Shantha GCBC Vaccines and marks the first stage at which vaccines are evaluated in people. Our Clinical Department designs and conducts ethically sound clinical studies with a strong emphasis on safety, efficacy, and informed consent, ensuring that all activities meet applicable regulatory and ethical standards. Pharmacovigilance is seamlessly integrated across the product lifecycle through continuous safety surveillance and systematic adverse event reporting. Together, these activities enable ongoing benefit–risk evaluation and ensure a robust and favourable benefit-risk profile for our vaccines.

Animal House

GCBC Vaccines also operates a modern Animal House spanning approximately 17,000 sq ft, purpose-built for preclinical vaccine research and fully compliant with Good Laboratory Practices (GLP).

The facility is staffed by trained personnel and designed to meet regulatory standards with controlled housing, observation, and procedural areas—playing a critical role in ensuring vaccine safety and efficacy through in vivo studies.